Maintenance of a CAC or ASHP

To ensure the system runs as efficiently as possible, a technician should perform the following services on an annual basis:

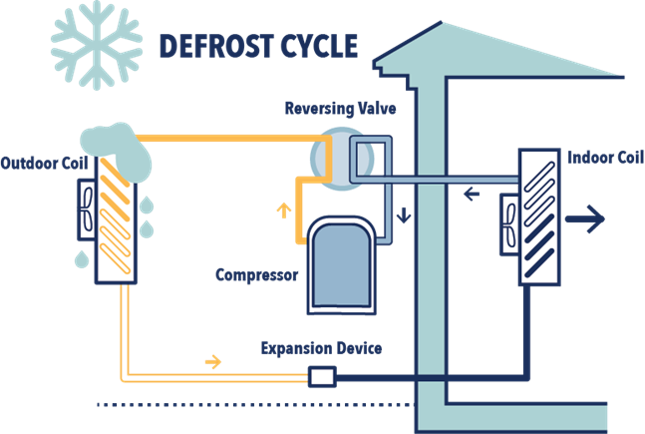

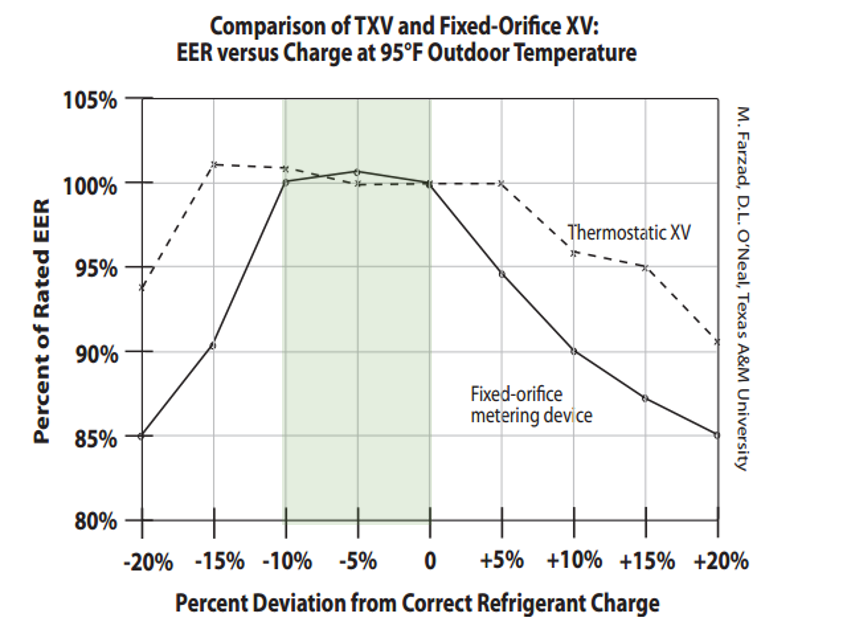

- Verify correct refrigerant charge and check for refrigerant leaks

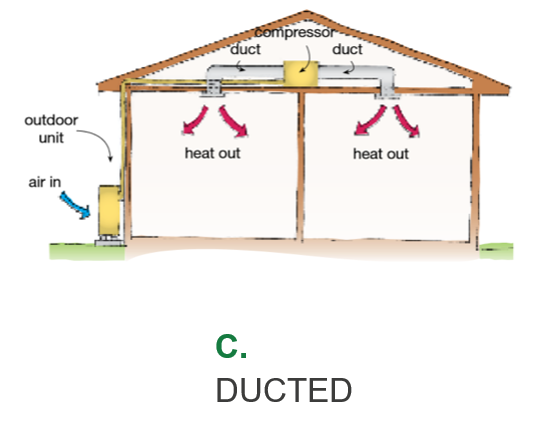

- Inspect and seal duct leakage

- Verify electric control and make sure that the heating system and cooling system cannot operate simultaneously

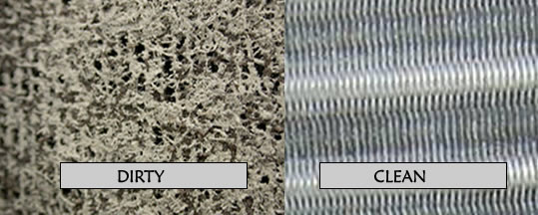

- Measure air flow through the system

- Inspect electric terminals, and, if necessary, clean and tighten connections, and apply nonconductive coating

- Lubricate motors, and inspect belts for tightness and wear

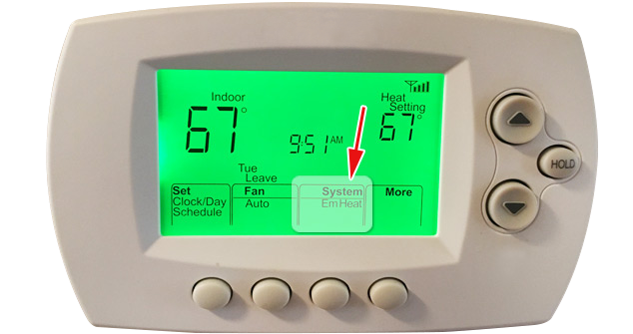

- Verify correct thermostat operation